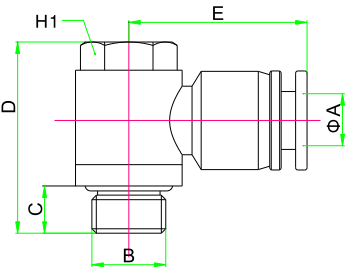

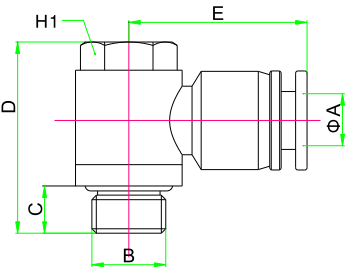

| UMZEKELO | A | B | C | D | E | F | H1(Hex) | Ubunzima(g) |

| PH04-M5 | 4 | M5*0.8p | 4 | 19 | 23.0 | | 8 | 6.5 |

| PH04-M6 | 4 | M6*1.0p | 4.5 | 19.5 | 23.0 | | 8 | 6.6 |

| PH04-01 | 4 | I-R1/8 | 7.5 | 24.5 | 21.4 | | 10 | 12.2 |

| PH04-02 | 4 | I-R1/4 | 9 | 30 | 23.1 | | 14 | 24.5 |

| PH06-M5 | 6 | M5*0.8p | 4 | 19 | 23.0 | | 8 | 7.6 |

| PH06-M6 | 6 | M6*1.0p | 4.5 | 19.5 | 23.0 | | 8 | 7.6 |

| PH06-01 | 6 | I-R1/8 | 7.5 | 24.5 | 23.6 | | 10 | 13.7 |

| PH06-02 | 6 | I-R1/4 | 9 | 30 | 25.3 | | 14 | 24.7 |

| PH06-03 | 6 | I-R3/8 | 10.5 | 34.5 | 27.2 | | 19 | 45.5 |

| PH06-04 | 6 | I-R1/2 | 12 | 41 | 30.1 | | 24 | 81 |

| PH08-01 | 8 | I-R1/8 | 7.5 | 24.5 | 25.0 | | 10 | 14.4 |

| PH08-02 | 8 | I-R1/4 | 9 | 30 | 26.7 | | 14 | 25.5 |

| PH08-03 | 8 | I-R3/8 | 10.5 | 34.5 | 28.6 | | 19 | 45.8 |

| PH08-04 | 8 | I-R1/2 | 12 | 41 | 31.5 | | 24 | 80.8 |

| PH10-01 | 10 | I-R1/8 | 7.5 | 24.5 | 29.2 | | 10 | 16.5 |

| PH10-02 | 10 | I-R1/4 | 9 | 30 | 30.9 | | 14 | 27.9 |

| PH10-03 | 10 | I-R3/8 | 10.5 | 34.5 | 31.1 | | 19 | 48.3 |

| PH10-04 | 10 | I-R1/2 | 12 | 41 | 34.0 | | 24 | 83.2 |

| PH12-02 | 12 | I-R1/4 | 9 | 30 | 32.7 | | 14 | 31 |

| PH12-03 | 12 | I-R3/8 | 10.5 | 34.5 | 34.6 | | 19 | 47.8 |

| PH12-04 | 12 | I-R1/2 | 12 | 41 | 37.5 | | 24 | 86.3 |

| UMZEKELO | A | B | C | D | E | F | H1(Hex) | Ubunzima(g) |

| PH04-G1 | 4 | G1/8 | 5.5 | 25 | 21.4 | | 10 | 12 |

| PH04-G2 | 4 | G1/4 | 6 | 29.5 | 23.1 | | 14 | 26 |

| PH06-G1 | 6 | G1/8 | 5.5 | 25 | 23.6 | | 10 | 14.2 |

| PH06-G2 | 6 | G1/4 | 6 | 29.5 | 25.3 | | 14 | 26.2 |

| PH06-G3 | 6 | G3/8 | 7 | 34 | 27.2 | | 19 | 35 |

| PH06-G4 | 6 | G1/2 | 9 | 39 | 30.1 | | 24 | 81.6 |

| PH08-G1 | 8 | G1/8 | 5.5 | 25 | 25.0 | | 10 | 14.9 |

| PH08-G2 | 8 | G1/4 | 6 | 29.5 | 26.7 | | 14 | 27 |

| PH08-G3 | 8 | G3/8 | 7 | 34 | 28.6 | | 19 | 43.3 |

| PH08-G4 | 8 | G1/2 | 9 | 39 | 31.5 | | 24 | 81.8 |

| PH1O-G1 | 10 | G1/8 | 5.5 | 25 | 29.2 | | 10 | 17.4 |

| PH10-G2 | 10 | G1/4 | 6 | 29.5 | 30.9 | | 14 | 29.4 |

| PH10-G3 | 10 | G3/8 | 7 | 34 | 31.1 | | 19 | 45.7 |

| PH10-G4 | 10 | G1/2 | 9 | 39 | 34.0 | | 24 | 83.8 |

| PH12-G2 | 12 | G1/4 | 6 | 29.5 | 32.7 | | 14 | 32.9 |

| PH12-G3 | 12 | G3/8 | 7 | 34 | 34.6 | | 19 | 48.7 |

| PH12-G4 | 12 | G1/2 | 9 | 39 | 37.5 | | 24 | 87.1 |

Ingqalelo nceda :Iingcaphulo kunye nokuhanjiswa kwezinto ezingezizo estokhweni zinikezelwe ngesicelo.Ulungelelwaniso kunye nemilinganiselo ixhomekeke ekutshintsheni ngaphandle kwesaziso.

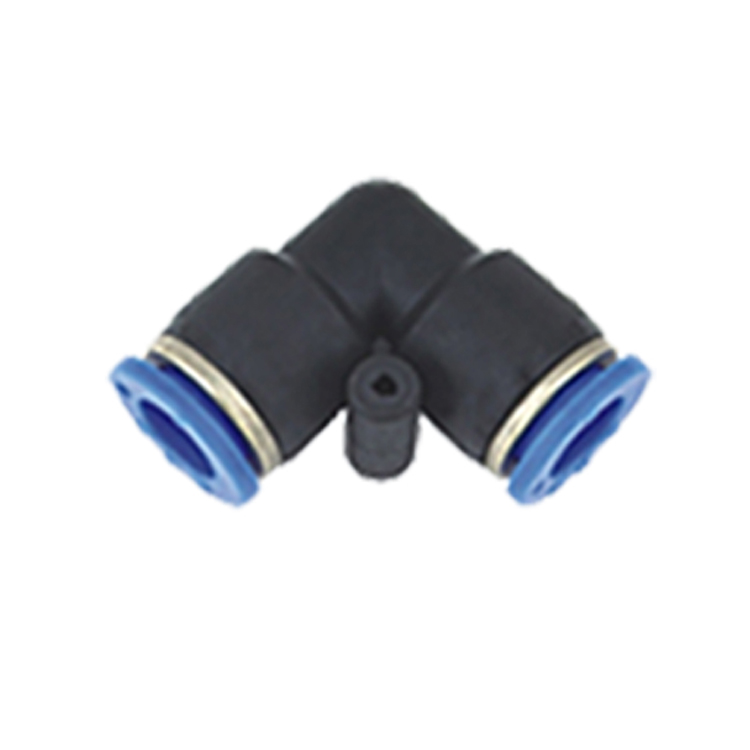

Izixhobo zePlastiki zokuPush-In

Iimbonakalo

- Ukufakela ngokulula kunye nokukhupha ngaphandle kwezixhobo.

- Indlela yokutshixa ityhubhu yensimbi engenasici.

- Umsonto wokutywina kwimisonto ye-taper, i-O-ring face seal kwimisonto ye-G.

- I-NBR njengesixhobo sokutywina esisemgangathweni, ezinye izixhobo ziyafumaneka xa ziceliwe.

- I-Nick plated isemgangathweni yonyango lomphezulu we-bass, iqinisekisa i-anti-corrosion kunye ne-anti-contamination.

- Isebenziseka kwakhona-Inokudityaniswa kwaye ichithwe ngokuphindaphindiweyo.(cebisa ukuba usike indawo eyonakele kumphezulu wombhobho)

- Umsonto: BSPP, BSPT, NPT (Nceda uqhagamshelane nathi ngezinye iindlela)

Inkcazo

| O-Ring Seal | I-NBR (ezinye izixhobo ziyafumaneka xa ziceliwe) |

| Ukubamba Mechanism | Yenziwe ngentsimbi eshayinayo |

| Uluhlu lobushushu | 32°F ukuya kwi-140°F |

| Uxinzelelo oluphezulu | 150 PSI |

| Umsebenzi weVacuum | 29.5 Intshi Hg |

| Media | Umoya ocinezelekileyo |

Qaphela: Ezi zithetha kuphela njengesikhokelo sokunceda kuyilo.Uvavanyo lommandla kufuneka lwenziwe ukufumana awona maxabiso esicelo sakho.

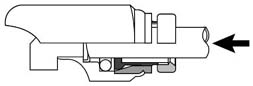

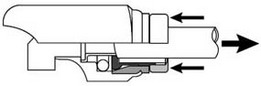

Imiyalelo yokuFakela

|  |

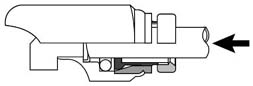

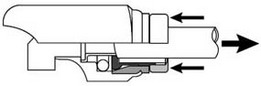

| Umfanekiso woku-1 | Umfanekiso wesi-2 |

Ukuqhagamshela ityhubhu (jonga umfanekiso 1)

- Sika iityhubhu ngokulinganayo–ubuninzi be-engile ye-15° buvumelekile.Ukusetyenziswa kwe-tube cutter (PTC) kuyacetyiswa.

- Khangela ukuba izibuko okanye indawo yokukhwelana icocekile kwaye ayinabo ubumdaka.

- Faka ityhubhu kwindawo efanelekileyo de ibe yi-bottom.Tyhiliza kabini ukuqinisekisa ukuba ityhubhu ifakiwe kwikholethi edlulileyo kunye ne-O-Ringi.

- Tsala kwityhubhu ukuqinisekisa ukuba ifakwe ngokupheleleyo.

Ukuqhawula ityhubhu (jonga umfanekiso 2)

- Cofa ngokulula iqhosha lokukhulula, ubambe ngokuchasene nomzimba, kwaye utsale i-tubhing ngaphandle kokufanelekileyo.

Ngaphambili: I-PHF Yasetyhini yeBanjo yePlastiki yePoly Push kwiTubhu ukuya kwizifakelo zeSidibanisi seAptha yoMbhobho Okulandelayo: I-PKM yobudoda yeSebe lePlastiki yePoly yokutyhala kwiThubhu ukuya kwizifakelo zesiqhagamsheli seAptha ye-Adapter